Buhler Twin Screw Technology

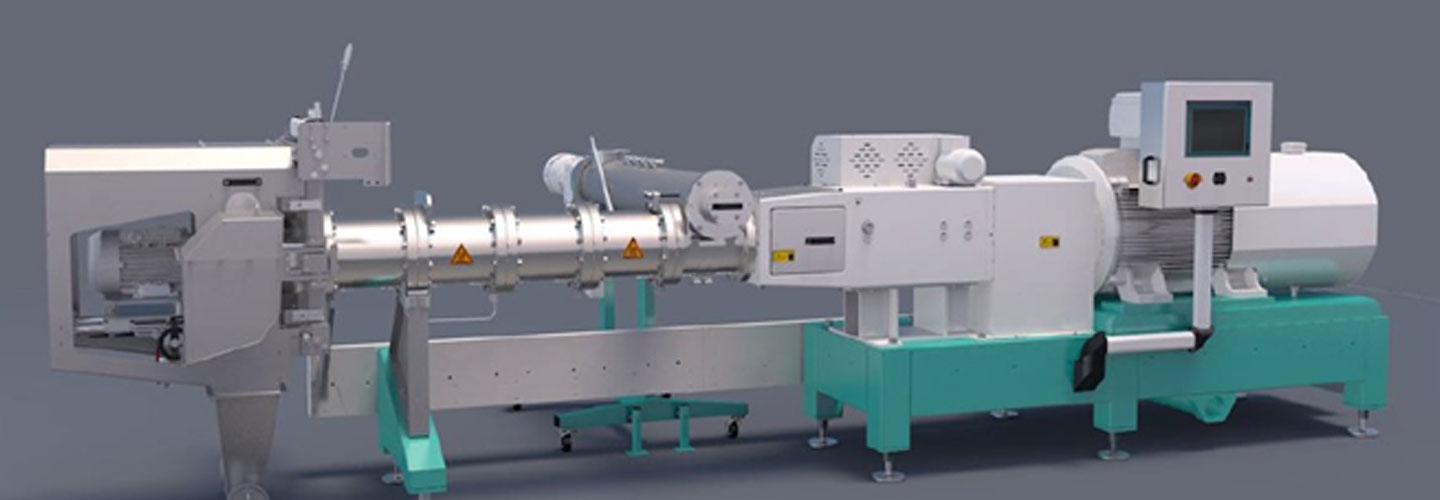

Our plant is equipped with Buhler’s Twin Screw Extrusion technology - Extruder Type CompacTwinTM BCCG-62/20D Machine.

Buhler is recognized as a significant contributor to the global burden of disease, micronutrient deficiencies underscore the urgency for effective solutions. Leveraging Buhler's versatile food processing technology, particularly the Extrusion Processing Technology including preconditioning, offers a robust solution for fortifying rice, addressing malnutrition challenges with efficiency and efficacy.

Advantages of Twin-Screw Extrusion

Twin Screw Extrusion (TSE) is a new technology with a lot of flexibility and vitality. Compared to a single screw extrusion cooking, a TSE can handle a number of ingredients such as,

a. Any ingredient with Lipid level more than 3%

b. Ingredients with higher Crude fiber level (greater than 5%)

c. Soy flour with less than 50 protein dispersability index

d. Soy protein isolate and concentrates

e. Sticky raw materials

Twin-Screw Extruder CompacTwin™. Major Customer benefits.

Well Known name in Extrusion Worldwide

• 700+ installations globally

• More than 70% Breakfast cereals in India is manufactured on Buhler Extrusion Systems.

High Product Quality

The twin screw extrusion process gives you almost unlimited control over the cooking process, and changes can be made quickly during cooking. This gives you complete control over the cooking and processing of your product. In addition, the HTST (High Temperature Short Time) cooking method on a TSE produces superior products. The high temperatures destroy harmful micro organisms, while minimizing the loss of nutrients or flavors in the food being produced.

Core system components from Buhler

The crucial process stages.

Preconditioner

In the preconditioner, two separate process operations take place: ingredient mixing and retention of the material to allow wetting/exposure to moisture.The preconditioner is available in six sizes ranging from 100 to 1600 liters’ holding capacity and processing capacities ranging from 100 to 20,000 kg/h

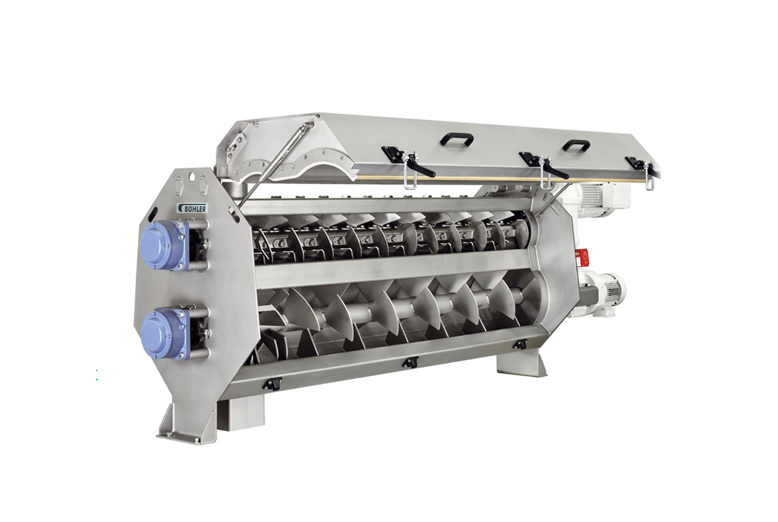

Twin-screw extruder

The modular twin-screw extrusion system covers the entire operating range from the laboratory scale to large-scale commercial production capacities. The configuration of the machine is carefully matched to the specific application process.

Fluid-bed dryer

The continuous fluid-bed dryer/cooler is excellently suited for the thermal treatment of extrudates with a particle size starting at 0.25 mm. The fluid bed, which is designed as a cross-current exchanger, fluidizes the individual product particles and dries/ cools them gently and efficiently across the entire bed length.

Fluid-bed dryer/toaster

The fluid-bed dryer/toaster with its forced con- veying action is applied for drying and toasting a wide variety of pellets and free-flowing materials. The modular chamber system allows the machine size to be selected that is ideally suited to the required retention time and material throughput.

Chinese vs Buhler Solution

| Sl. No. | Chinese Machinery | Buhler Solution |

|---|---|---|

| 1 | The system works with two feeders and a mixing system. This can lead to some non-homogeneity as the ratio of the ingredients to main flour is very small. | Buhler works with 2 loss in weight feeders for rice and additives of different sizes. They feed directly and simultaneously to the preconditioner and assure highest level of consistency and maintain a proper ratio of the flour and additives. Better Quality and homogenous product. |

| 2 | The premix is further conveyed using pneumatic system. This can further lead to separation and non-homogeneity of the product. |

Direct feeding to pre-conditioner. No separation issues. |

| 3 | Feeding to the Extruder is volumetric. This can lead to non-homogenous product and issue with consistency in case there is bridging or changes in bulk density of the product. | Feeding is gravimetric. More precise dosing irrespective of the changes in density. Consistent product quality. |

| 4 | No preconditioner. Less gelatinization degree. | Twin stage preconditioner. Better gelatinization, stable kernels, and retention of nutrients. |

| 5 | No density control (vacuum system), to control density of the product | Control of density of product to match the product to be added. Reduces chances of separation during storage. |

| 6 | Product looks more like a pellet | Laser cut dies to match the product shapes to maximum extent |

| 7 | 4 x Extrusion lines – difficult to get consistent quality | One Extruder – Easy to operate, control. Consistency and repeatability |

| 8 | 4 x Extrusion lines – two dryers – difficult to control moisture | One extruder feeding to one dryer. Precise moisture control. |

| 9 | Dryer with Teflon belt – prone to sagging due to heating and cooling. Can also create choking and inconsistent air flow. More maintenance. | Dryer with steel belts. No sagging, maintenance, choking. |

| 10 | PLC, HMI, drives from local Chinese manufacturers. | Components from manufacturers like Siemens, Schneider. |

| 11 | Higher space requirement. | Lower space requirement. |

| 12 | Higher energy costs (Workings shared in separate file) | Lower energy cost. |

| 13 | Basic control of the equipment | Complete recipe based system with plant control system and IOT enabled. |

| 14 | Product stability, uniformity and nutrient retention a concern. | Proven product stability and nutrient retention. |

| 15 | Machine designed for 4-5 years life. | Machines built to last. |

| 16 | No service support – No local presence. | Reliable Buhler Service – Local presence |

Key Highlights of Buhler Fortified Rice solution

- 1. Long experience in making Plant and Equipment for Fortified Rice Kernel – Since 2004.

- 2. 28 Proven process and process expertise – Producing NutririceTM since 2009. Since 2004.

- 3. Established Process Control – To achieve different product characteristics and do them consistently.

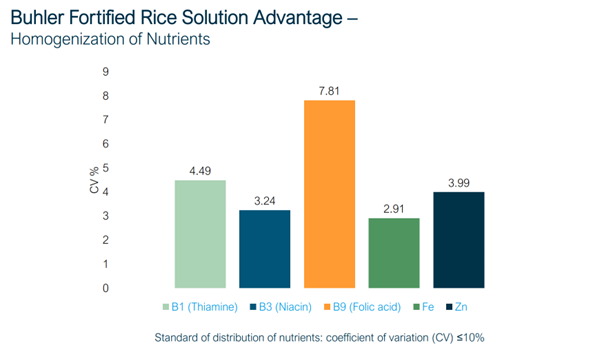

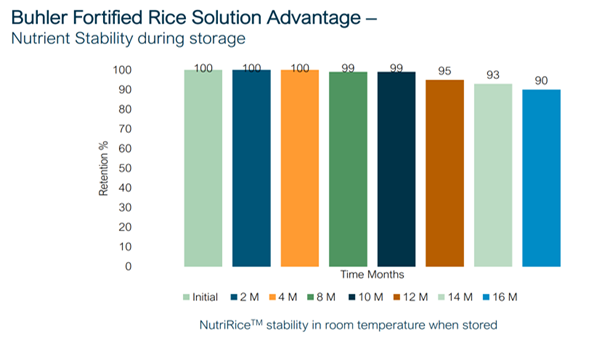

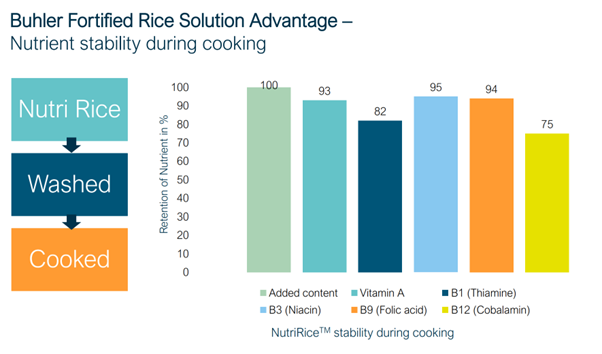

- 4. Better Product – Better Homogenity; Better Stability; Better Nutrient Retention.

- 5. Proven Efficacy – By various efficacy tests carried out by the end users throughout the world.

- 6. Robust and Top Quality Equipment - Reliability of Process and Equipment.

- 7. Aftersales Support - Local Process and Aftersales Support, Remote Support.